» Hydraulic Tank Jacking Equipment

Detailed Description of complete hydraulic

jacking unit and assembly of lifting trestles.

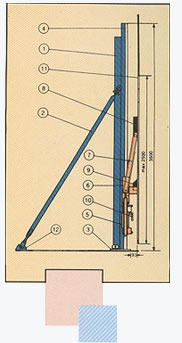

A jacking unit as illustrated in the

adjacent figure, consists of the following components: To Construct Steel Storage Tanks, Diesel, Petrol,Oil, etc

- Upright, Height 3, 500 mm

- Adjustable stay

- Base plate with attachment for upright

- Jack rod

- Hydraulic jack

- Slipper

- Lifting arm

- Lifting lug (welded to shell plate)

- Guide (welded to shell plate)

- Shut-off cock coupling for high pressure hose

- Shell plate

- Stay lug (welded to base plate).

The number of jacks required is determined by the size and

weight of the tank

|

|

Product Details:

| Pattern | Hydraulic Tank |

| Stay | Adjustable |

| Upright Height | 500 mm |

| Type | Jacking Equipment |

| Color | Yellow |

| Brand | Bell |

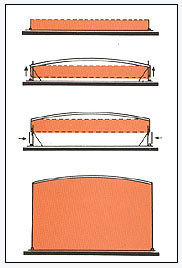

Principle of assembly of hydraulic tank

jacking equipment:

- The foundation is made ready

- The base is laid out and welded

- The periphery of the tank is marked out on the base plate

- Guide trestle for the shell plate are erected

- The top shell plates are erected and welded vertically.

- The roof trusses are assembled and joined to top shell

- Lifting trestles with hydraulic jacks are fitted internally along

with the periphery of the tank

- Lifting lugs and guides are welded to the shell plate.

- The top shell plate and the roof construction are lifted one

plate height.

- The roof plate is fitted and welded in place. At the same time,

the next shell plate is fitted and welded

- The lifting lugs and guides are removed from the top shell plate

and new lugs and guides are welded to the nest shell plate. The

hydraulic jacks are lowered to the original lifting position

- The tank is lifted again to allow the continued erection of shell

plate until the full height of tank has been reached.

- When the last shell plate is fitted and welded in place, the

finished tank is lifted slightly so that the guide trestles can be

dismantled.

- The tank is lowered and the shell plate and base plate are welded

together.

- The jacking equipment is dismantled.

|

|

Advantages

- Welding done at ground level.

- Easy access for inspecting quality of welding

- Roof is fixed to the top shell plate from the commencement

rendering it stable against WIND-LOAD throughout the erection work.

- Guide trestles stabilize the tank at the bottom maintaining its

circularity and accuracy

- Need of scaffolding is eliminated

- Highest - Safety achieved as working is carried out at ground

level.

- Economy - Cost effectiveness achieved as labour and time required

is minimized

|